Historic Preservation with Fire Rated Glass

Historic Preservation with Fire Rated Glass. This article from USGNN talks about how fire rated glass was used to blend a new addition to the historic University of Michigan Law School.

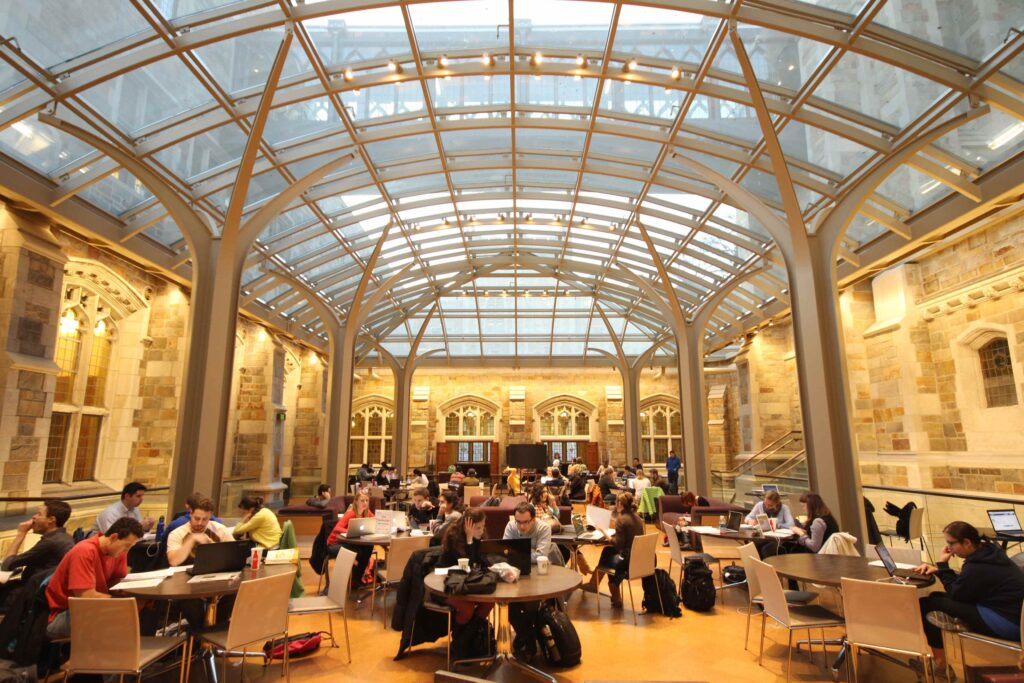

The University of Michigan Law School Academic Building and Hutchins Hall Student Commons addition is part of major renovation not seen since the opening of Hutchins Hall in 1933. The construction project broke ground in September 2009, and the Student Commons officially opened in fall 2011, featuring a unique use of fire-rated glass.

“With the introduction of a newly constructed Student Commons located within an existing outdoor courtyard at the University of Michigan Law School, a two-hour fire-rated barrier between it and the existing building was required by code,” says Ross Winiemko, project manager at Edwards Glass in Livonia, Mich. “This presented an issue with regards to keeping with the original appearance of the building that includes historic stained glass murals, aged limestone, and a building rich with tradition.”

Edwards Glass was the glazing contractor and installer in the project.

To accomplish the design intent, Safti First Superlite IIXL Transparent fire-rated glass and Interior EZ Framing Systems were used in two creative installation methods, Winiemko says. “The first included installing the 1 ½-inch high-performance fire-rated glazing within a tube steel structure with Safti’s framing, surrounded by decorative limestone, followed by being sandwiched on both sides with restored stained glass and newly created stained glass to match the existing,” he says. “The second method included installing custom framing provided by Safti against existing stained glass at multiple areas capped with decorative millwork that essentially focuses the user’s attention to the new Student Commons area without a second thought as to the fire-rated protection that is being looked through.”

The everyday person accessing the entrances or looking through these advanced fire-rated systems, hardly notice the difference in framing or glass, Winiemko says. “This is the exact reason why the role in the systems offered will play a pivotal role in this and future projects – high end protection – that is hidden in the design.”

Safti First supplied 70 openings in various pattern cuts, says Diana San Diego, director of marketing at Safti First in San Francisco. “It’s a combination of SuperLite II-XL 45 and SuperLite II-XL 120 with the Safti First EZ Framing System. The stained glass was preserved from the original building. Additional stained glass was replicated by Full Spectrum Stained Glass Inc.,” she says.

Integrated Design Solutions in Troy, Mich., and Hartman-Cox in Washington, D.C., were the architects on the project.

“It’s a challenge every time a building team embarks on work that involves historic preservation,” San Diego says. “You definitely have to bring everything up to code (fire safety included) but be respectful of the original design.” Finding a creative solution that preserved the building’s collegiate gothic look was important to the university and the architects. “This is where Edwards Glass, Safti First and the architects got together and came up with a way to preserve the stained glass and aged limestone by combining it with clear, fire resistive SuperLite II-XL,” she says.

“When a fire-rated wall is necessary due to code restrictions, having an open mind using creative design techniques with a qualified glazing professional is the best way to ensure optimal efficiency in design and performance,” Winiemko says.

The implementation of the design was a large part of the success, Winiemko says. “Mike Kalil, project superintendent with Walbridge Aldinger of Detroit, Mich., did a phenomenal job of coordinating the trades during the course of the project,” he says. “Although the design is of upmost importance, the challenge that we all face is the time frame in which to execute without sacrificing quality of the installation. This is where planning and preparation was paramount in which our installation crews in sequence with other trades performed.”

Source: US Glass News Network, December 16, 2011, by Sahely Mukerji